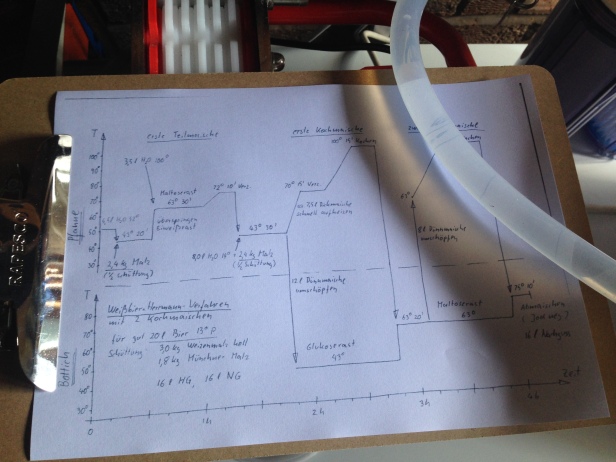

In his paper, Markus Herrmann (TU-Munich, Weihenstephan) describes a mash schedule better suited for wheat beers to enhance the formation of Ethyl Acetate and Isoamyl Acetate. These esters are mainly responsible for what is known as the “banana aroma” in Wheat Beers. Formation of these esters requires Glucose. During a regular mash only 10% of Glucose and 90% Maltose are formed. The “Herrmann Verfahren” enhances the production of Glucose via Maltase, which is most active at 38C and denatures above 62C.

Here is how it works in a nutshell:

- The grain bill is split 50:50 and the first half is then mashed.

- Mash in at 38C

- Convert Maltose at 62C

- Now water is added, cooling the mash down to 45C

- Add the rest of the grain and maintain that temperature for a period to allow the Maltase to split the now existing Maltose into Glucocse

- Then proceed as normal

Note that 45C is a bit higher than the optimum for maltase, but it also allows for better creation of Ferulic acid, responsible for the clove taste in wheat beers.

And here is how it works in detail:

Note that I don’t use software like BeerSmith for the mash part. It simply cannot cope with this kind of schedule, and although it claims to support decoctions, it only supports it poorly by not showing how the decoction part itself is converted.

Ingredients

| Wheat Malt | 60% |

| Munich Malt | 40% |

| Yeast | Weihenstephan W68 |

| Water | Didsbury municipal |

| Hops | Hallertau Mittelfrüh |

- First half of the grains are added to the mash tun

- Add water to achieve a thick mash (3:1) at 43C and rest for 20 minutes.

- Add water to achieve 63C and wait for 30 minutes (5:1)

- Heat to 72C to help the alpha amylase do a bit of work. 10 minutes.

- Add the rest of the water to bring the temperature down to 43C (5:1), 30 minutes

- 1st Decoction. Convert the thick mash at 70C for 15 minutes, then boil at 95C for 15 minutes

- Slowly return the thick mash to achieve a total temp of 63C. 20 minutes

- 2nd Decoction. Thin decoction and boiled at 100C for 25 minutes.

- Thin decoction returned to mash to raise temperature to 75C

- Total mash time: 4h

Some people may recognise the last part as the “Hochkurz” method, as used by most Bavarian breweries. You may replace the decoction part with an infusion mash if you prefer, note however that you won’t make certain caramels and need to compensate by adding some type of Caramalt to the grain bill. It won’t have the same taste though, no matter which Caramalt is used, but it’s close enough. Weyermann’s Carahell is a good starting point.

It’s a very laborious schedule but the results are worth it!

Great read and I will definitely give this a try. One question though, in your mash/decoction schedule, it doesn’t seem to mention when the final half of the grains are added? Does this come after step 5?

LikeLike

They’re added in step 5 with the additional water.

LikeLike

Excellent article , thanks.

What temp is recommended if using an infusion instead of decoction ? 63c ?

A ph of 5.6 maintained throughout the whole process?

What is an ideal pre fermentation range for the ph?

Sorry for questions!

LikeLike