Columbia University Northwest Corner Building Facade

Columbia University Northwest Corner Building Facade

Columbia University Northwest Corner Building Facade

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Columbia</strong> <strong>University</strong><br />

<strong>Northwest</strong> <strong>Corner</strong><br />

<strong>Building</strong> <strong>Facade</strong><br />

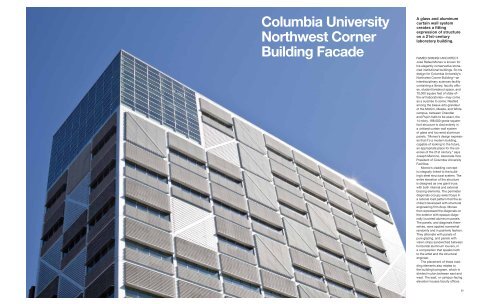

A glass and aluminum<br />

curtain wall system<br />

creates a fitting<br />

expression of structure<br />

on a 21st-century<br />

laboratory building.<br />

FAMED SPANISH ARCHITECT<br />

José Rafael Moneo is known for<br />

his elegantly conservative stoneclad<br />

institutional buildings. So his<br />

design for <strong>Columbia</strong> <strong>University</strong>’s<br />

<strong>Northwest</strong> <strong>Corner</strong> <strong>Building</strong>—an<br />

interdisciplinary sciences facility<br />

containing a library, faculty offices,<br />

student breakout space, and<br />

70,000 square feet of state-ofthe-art<br />

laboratories—may come<br />

as a surprise to some. Nestled<br />

among the beaux-arts grandeur<br />

of the McKim, Meade, and White<br />

campus, between Chandler<br />

and Pupin halls to be exact, the<br />

14-story, 188,000-gross-squarefoot<br />

structure is clad entirely in<br />

a unitized curtain wall system<br />

of glass and louvered aluminum<br />

panels. “Moneo’s design expresses<br />

that it’s a modern building,<br />

capable of looking to the future,<br />

an appropriate place for the sciences<br />

of the 21st century,” says<br />

Joseph Mannino, Associate Vice<br />

President of <strong>Columbia</strong> <strong>University</strong><br />

Facilities.<br />

Moneo’s cladding concept<br />

is integrally linked to the building’s<br />

steel structural system. The<br />

entire elevation of the structure<br />

is designed as one giant truss<br />

with both internal and external<br />

bracing elements. The perimeter<br />

diagonals occupy select bays in<br />

a rational load pattern that the architect<br />

developed with structural<br />

engineering firm Arup. Moneo<br />

then expressed the diagonals on<br />

the exterior with opaque diagonally<br />

louvered aluminum panels.<br />

The panels, and diagonals themselves,<br />

were applied somewhat<br />

randomly and in painterly fashion.<br />

They alternate with panels of<br />

pure glazing, and panels with<br />

vision strips sandwiched between<br />

horizontal aluminum louvers, in<br />

a composition that speaks both<br />

to the artist and the structural<br />

engineer.<br />

The placement of these cladding<br />

elements also relates to<br />

the building’s program, which is<br />

divided in plan between east and<br />

west. The east, or campus-facing<br />

elevation houses faculty offices<br />

22 Metals in Construction Fall 2010 23

Left The facade expresses the building’s<br />

truss diagonals.<br />

Below left Four 18-foot-8-inch-high by<br />

5-foot-wide panels make up each bay of<br />

the double-height lab floors.<br />

Previous spread A glass-enclosed<br />

lounge looks north to upper Manhattan.<br />

Right The east elevation is clad with<br />

glass, exposing activity in offices and<br />

student spaces to the campus.<br />

and student breakout spaces,<br />

whereas the west face, which<br />

looks out on Broadway, houses<br />

the laboratory functions. While the<br />

labs boast generous 18-foot floorto-floor<br />

heights, the offices are<br />

subdivided in mezzanines, two<br />

per lab floor, creating an interesting<br />

tension between the two sides<br />

of the building. Moneo clad the<br />

east face entirely in glass, with the<br />

exception of its connection with<br />

Pupin Hall, where the louvered<br />

aluminum panels are used. This<br />

arrangement puts the indoor<br />

activity on view to the campus, an<br />

effect that the architect likens to a<br />

beehive. The lab side of the building,<br />

where more concentration<br />

is called on from the occupants,<br />

features the majority of the diagonally<br />

louvered opaque panels and<br />

the horizontally louvered vision<br />

strip panels. Again there is an<br />

exception, at the upper left hand<br />

corner of the elevation, where the<br />

all- glass system takes over.<br />

Executive architect Davis<br />

Brody Bond Aedas and facade<br />

consultant R.A. Heintges<br />

Associates honed this cladding<br />

concept into a unitized curtain<br />

wall system. In the unitized<br />

system, four 18-foot-8-inch-highby-5-foot-wide<br />

panels make up<br />

a single bay of the double-height<br />

lab floors. On the office floors,<br />

the all glass modules are of the<br />

same dimensions, though they<br />

are made up of two glass lites<br />

placed one atop the other, so they<br />

read as half as high. The 1-inchthick<br />

insulated glass units are a<br />

standard product, VE12M from<br />

Viracon. In the metal system they<br />

have ¼-inch outer and inner lites,<br />

though in the all-glazed condition<br />

they come with a 3/8-inch outer<br />

lite, and a ¼-inch inner lite. The<br />

extra thickness on the outer lite<br />

helps to prevent wave distortion<br />

and pillowing. The IGUs also feature<br />

thermally broken, warm-edge<br />

spacers—stainless steel spacers<br />

between the glass lites that offer<br />

higher thermal performance than<br />

Left: Adam Friedberg; top: Turner Construction; previous spread: Adam Friedberg<br />

Adam Friedberg<br />

the typical aluminum spacers.<br />

The system was fabricated in<br />

a collaborative effort between curtain<br />

wall contractor W&W Glass<br />

Systems, Inc., Canadian firm Sota<br />

Glazing Inc., and Kansas Citybased<br />

metal experts A. Zahner<br />

Company. Zahner provided the<br />

aluminum panels and louvers,<br />

which snap into the Sota-built the<br />

curtain wall system. W&W erected<br />

the completed system on site.<br />

“It’s very hard to get decent color<br />

control with anodized aluminum,”<br />

explains Heintges. “You can’t<br />

just start mixing up batches as<br />

any slight variation in the alloying<br />

constituents will cause a different<br />

color. We had to keep a tight<br />

control on the source of aluminum<br />

and keep in close contact with<br />

Zahner and Sota.<br />

The cladding system includes<br />

more than 1,000 panels and<br />

construction manager Turner was<br />

pressed to keep the site orderly<br />

and moving smoothly. Because<br />

of the building’s configuration<br />

there was not a lot of room to<br />

store panels onsite before they<br />

were put in place. Turner had to<br />

carefully coordinate trucking and<br />

installation in an intricate threeday<br />

cycle with two rigs on the<br />

roof chasing each other around<br />

and around the building while<br />

W&W’s ornamental ironworkers<br />

clipped the system into place. All<br />

in all, it took six months to erect<br />

the facade, no shabby figure.<br />

Maninno is excited. “We’re ready<br />

to occupy this building in the fall,”<br />

he says, “and cap off three and a<br />

half years of construction.” !<br />

COLUMBIA UNIVERSITY NORTHWEST CORNER BUILDING FACADE<br />

Location: Broadway and West 120th Street, New York, NY<br />

Owner: <strong>Columbia</strong> <strong>University</strong>, New York, NY<br />

Design Architect: Rafael Moneo Valles Arquitecto,<br />

Moneo Brock Studio, Madrid, Spain<br />

Architect of Record: Davis Brody Bond Aedas, New York, NY<br />

Structural Engineer: Ove Arup & Partners Consulting Engineers, PC, New York, NY<br />

Mechanical Engineer: Ove Arup & Partners Consulting Engineers, PC, New York, NY<br />

Construction Manager: Turner Construction Company, New York, NY<br />

Curtain Wall Consultant: R.A. Heintges & Associates, New York, NY<br />

Structural Steel Erector: DCM Erectors, Inc., New York, NY<br />

Miscellaneous Iron Fabricator and Erector: Post Road Iron Works, Inc., Greenwich, CT<br />

Ornamental Metal Fabricator and Erector: Empire City Iron Works, Long Island City, NY<br />

Curtain Wall Fabricator: Sota Glazing Inc., Brampton, ON<br />

Curtain Wall Erector: W&W Glass, LLC, Nanuet, NY<br />

Metal Deck Erector: Solera / DCM, New York, NY<br />

24 Metals in Construction Fall 2010 <strong>Columbia</strong> <strong>University</strong> <strong>Northwest</strong> <strong>Corner</strong> <strong>Building</strong> <strong>Facade</strong><br />

25