Chet Herbert’s Beast IV

CHET AND HIS BEASTS

Written By: Curtis Hayes Cummings

New Photos By : Tim Sutton

Old Photos from : Kellogg auto archive unless noted

The streets of postwar Los Angeles were more than automotive corridors and dark locations for backlit crime films. A small, but growing cultural movement prowled the back streets and boulevards, searching for kicks in modified jalopies that could be built from almost anything with four wheels. Soon to be known as hot-rodders, these young backyard mechanics and tinkerers used the smooth L.A. asphalt as drag strip, cruising thruway and test track. Hot Rods were still slower than motorcycles and a wildman named Chet Herbert earned a reputation with his street antics aboard his modified Harley. Inspired by his mechanic uncle, Chet showed aptitude for all things mechanical, especially those things that burned gasoline. The kid had ambition and seemed set for great things, when at the age of 20, he was struck down by polio. The iron lungs of the day didn’t help and he would remain in a wheelchair for the rest of his life.

What could have easily derailed a lesser man’s life was shrugged off. Chet Herbert was made of strong stuff and he immediately pushed forward with his plans to develop racing parts and then get them out on the tracks. He applied some of his ideas to motorcycles, stripping and tuning a Harley-Davidson that would become known as The Beast due to it’s rough, unattractive appearance. In 1950 bikes were still more than competitive against early dragsters and at the Santa Ana drags that year, Chet’s growling dual-carb’d Beast beat every other bike and every four-wheeled racer as well.

Chet took notice that Harley had been using roller lifters since 1929 and no one had yet adapted the technology to automotive engines. At the time, he was building a Chevy Six for a customer to be used in a circle-track racer and he realized the potential that this motorcycle tech could offer. After striking out with all the L.A.-area camshaft manufacturers, Chet bought a basic lathe from Sears and then modified it into a camshaft grinder. Chet’s new cam and some shrewd tuning tricks would turn that Chevy Six into a 275hp fire-breather. That was superior power to the much more expensive Offenhauser engines that were then battling it out in circle-track. Predictably, word of Chet’s breakthrough spread quickly and Chet Herbert Cams was established. His speed shop would quickly become a necessary destination for anyone looking to go fast and Herbert Cams would become synonymous with high-power engines.

With business booming, Chet continued to develop his roller camshafts and to satisfy his thirst for competition, built Beast II, an incredibly rough-looking slope-nosed hotrod that made appearances at drags and dry lakes competitions. It’s sawed-off and Frankenstein’d Tudor body and general “unsafe at any speed” appearance drew shaking heads but the big “Herbert Cams” lettering made sure the shop phone was ringing with inquiries. Recognizing the promotional value that went along with breaking speed records, Chet started planning an all-out assault on Bonneville with a new futuristic streamliner that would be like nothing else on the salt.

The Beast I , Located now at the NHRA Museum at the Pomona fairplex where it will stay on display. Photo By Tim Sutton

Beast III

Beast III at the starting line at Bonneville. Photo donated by Mike Nichols

Chet Herbert had been thinking differently and innovating from his first days spent in the garage with his Harley. Hopping up engines had long been the easiest way to achieve increased straight-line speed. Recently, streamliners had been proving themselves to be the most efficient way to cut through the wall of air resistance and set outright speed records. Belly tankers had been playing around with aerodynamics since immediately after the war but were limited by their uniform shapes. The Xydias & Batchelor So-Cal Streamliner and the Kenz Twin Ford Streamliner had been upping both the hot rod game and the achievable speeds. These cars were built by garage hot rodders applying all the ingenuity and knowledge that they could scrape up and they were amazingly successful. As advanced as they looked from the outside, their sleek bodies were shaped by the simple concept of reducing frontal area and covering the wheels to allow air to flow over and around the car at speed. The final shapes were, at heart, just what the builders put their minds to and thought looked right.

Chet started Beast III with a long list of new ideas. Obtaining a partial chassis built with two three inch tubular sections from Paul Silva, Chet began to revise and reconstruct the chassis to accommodate a mid-mounted engine and a forward cockpit.

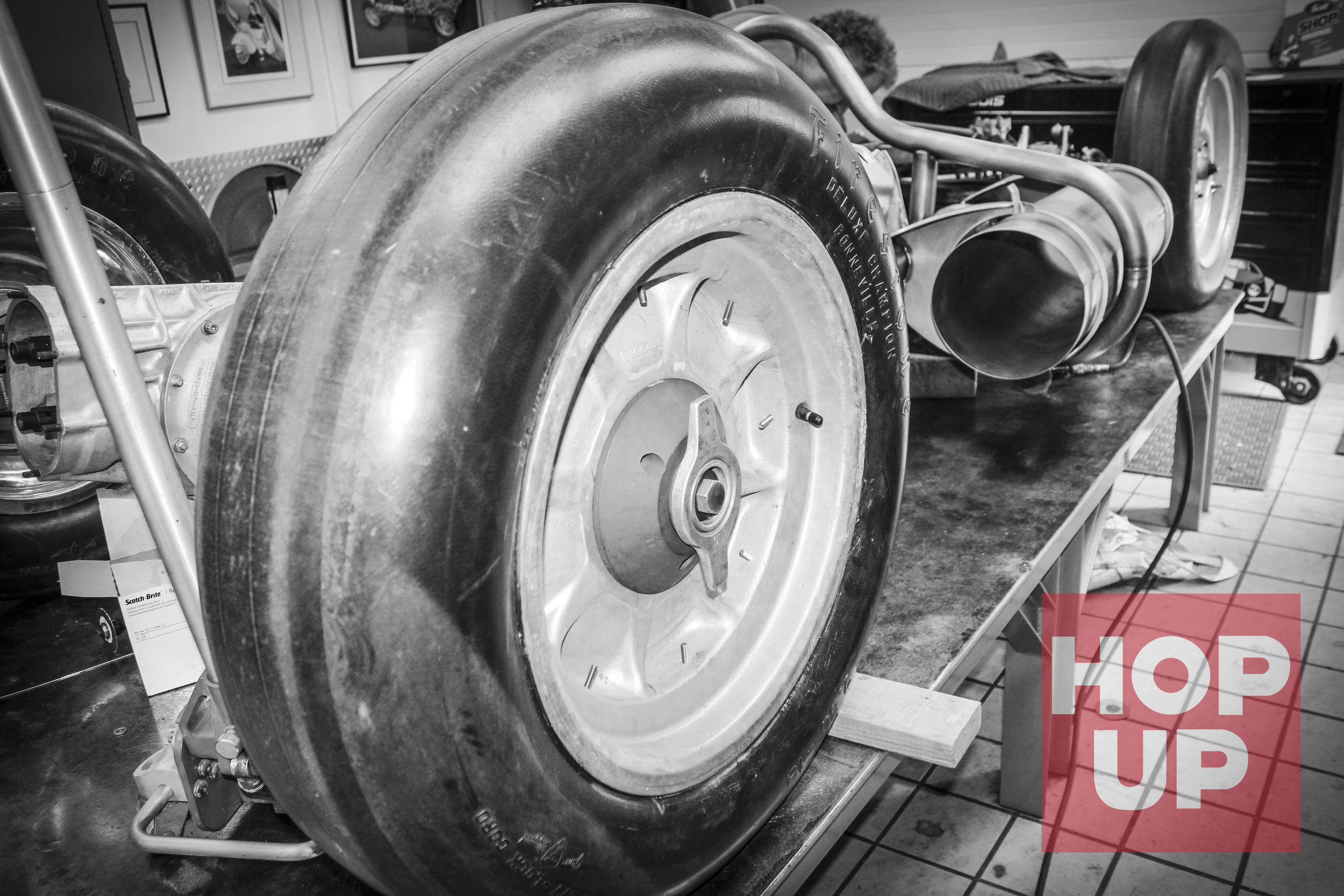

His desire to innovate and introduce new technologies led him away from traditional V-8 power to a modified 330ci aluminum Franklin 6cyl aircraft engine. He had been experimenting with this powerplant and was impressed with its low weight and power. Unfortunately, his plans for this engine exploded along with the motor during dyno testing at Tony Capanna’s shop. With the clock ticking toward Speed Week, Chet had to make a quick call and decided on proven Chrysler Hemi Power, which at the time was the hardest-hitting V-8 available. Dana Fuller came up with a suitable motor and Chet tore into it, modifying it to take a Vertex magneto and Hilborn fuel injection. Chet was serious about everything that went into this planned assault on the existing Bonnevillespeed records. Only top-quality parts were to be utilized, which included a Halibrand quick-change tube axle unit with an aircraft-type spot brake and 18 inch Halibrand magnesium wheels shod in Firestone rubber. With the chassis and engine laid out, Chet’s design showed purpose and potential. The roughness of Beast II was nowhere to be seen. Most importantly, there was an ace up his sleeve when it came to the bodywork. Seeing untapped potential in streamlining that had not yet been exploited by other builders, Chet Herbert set out to up the game and change the way that land speed cars were conceived.

Enter Rod Schapel.

Los Angeles, in the early ‘50s was the center of the aviation industry. Chet wanted to transcend the garage-built hot rod heart of the car with actual science. A lot of young aerospace engineers were messing around with hot rods in their spare time. Chet connected with a talented consultant named Rod Schapel who was working with Cal-Tech’s recently built wind tunnel. An actual mechanical engineer, Schapel’s specialty was studying airplane shapes and how they reacted to stresses and loads. Chet pitched his idea to build a Bonneville streamliner according to real aerodynamic principles. And there was one more thing- there was only a few months to get it done before Speed Week began in August. Schapel was in.

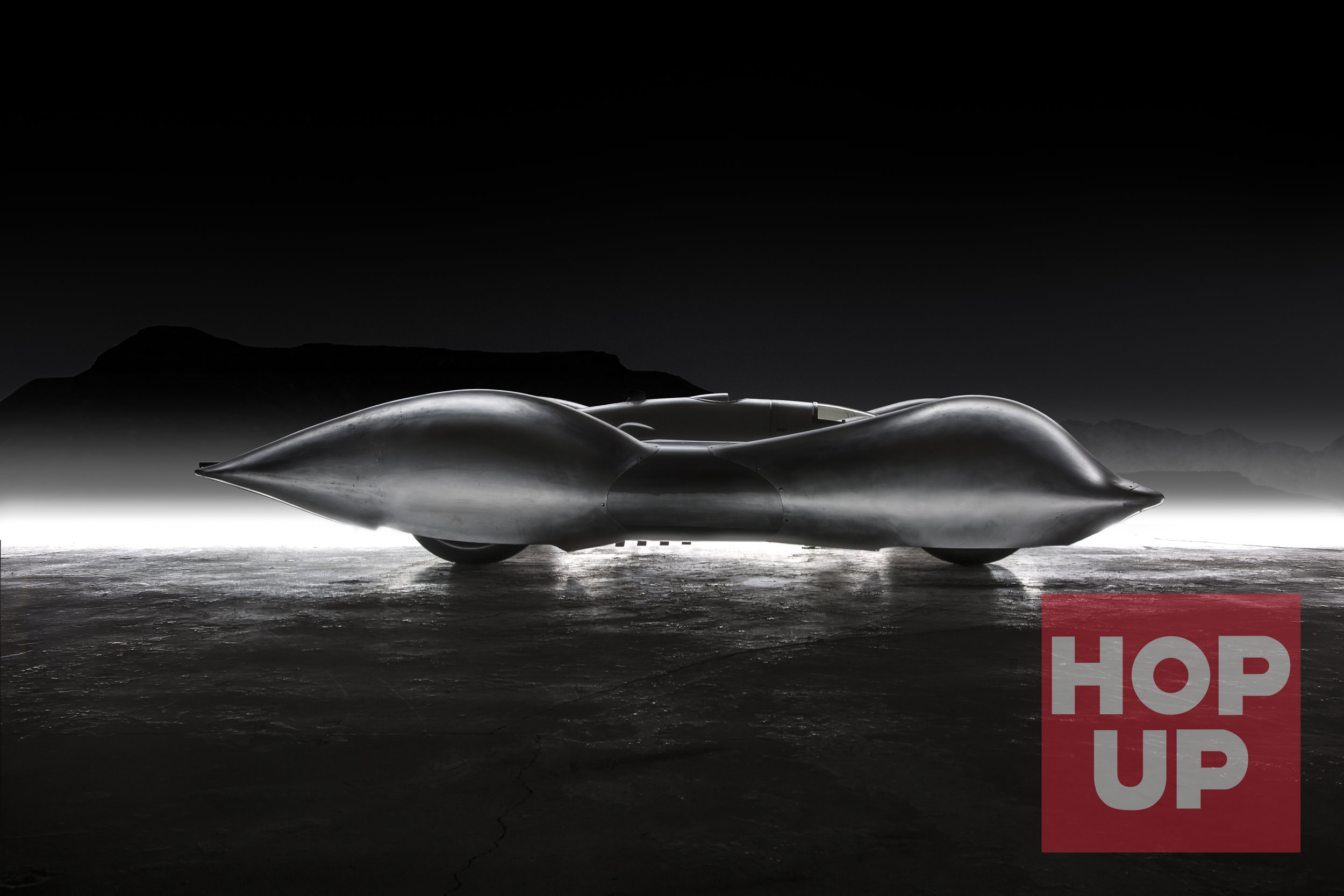

With a wartime sense of urgency, the young engineer went to work. Creating a 1/10th scale model of the car, he found wind tunnel time and began studying test data. Refining the shape to make the car as slippery through the air and as stable on the ground as possible, Schapel, who knew nothing of previous streamliners and had never been to Bonneville, came up with a timeless body that was both beauty and Beast.

In the early ‘50s, fiberglass was looked at as a new wonder material that would allow unprecedented freedom in the moulding process. Streamliners up to this point had bodies pounded out of aluminum or even heavier steel. Again wanting to innovate, Chet chose fiberglass. Schapel built a 20 foot mold in his backyard. The hand lay-up took two full months to complete. The date with the salt loomed closer and closer. Chet realized that more help was going to be needed with the project. Word had been trickling out around the hot rod community about the new Chet Herbert Bonneville car and volunteers began showing up. Chet’s focus on the car was infectious and his friends at the Chrisman & Sons Garage, in Compton, turned their whole workspace over to the Beast III project. In what would be a recurring scene throughout Chet’s life, he worked 24-hours a day for days at a time, sometimes being tied into his wheelchair so he wouldn’t fall out when he dozed off for short rests. It has been noted that his dedication and endless motivation inspired others around him to work harder and achieve things that they otherwise wouldn’t have believed. This is the mark of any great leader.

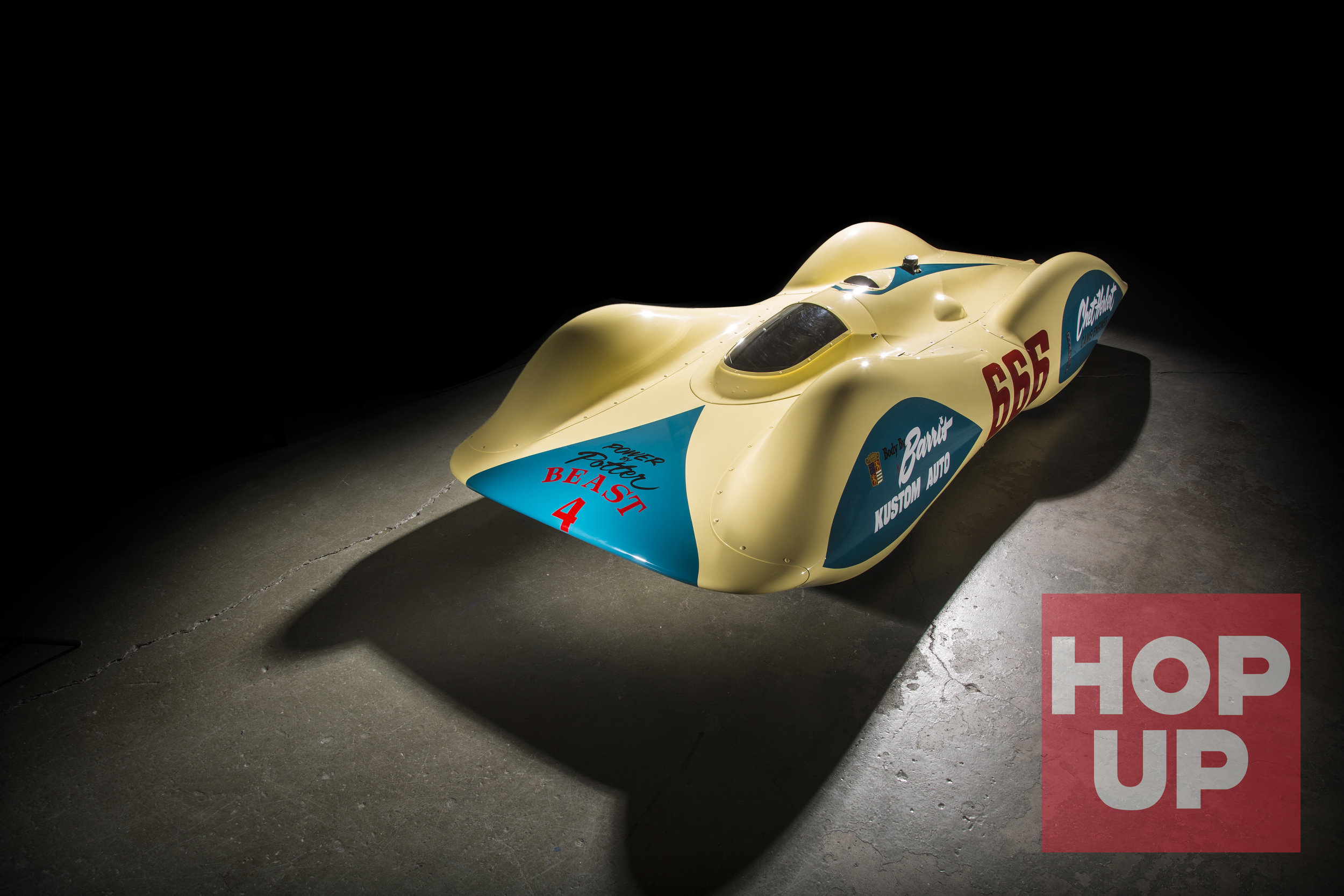

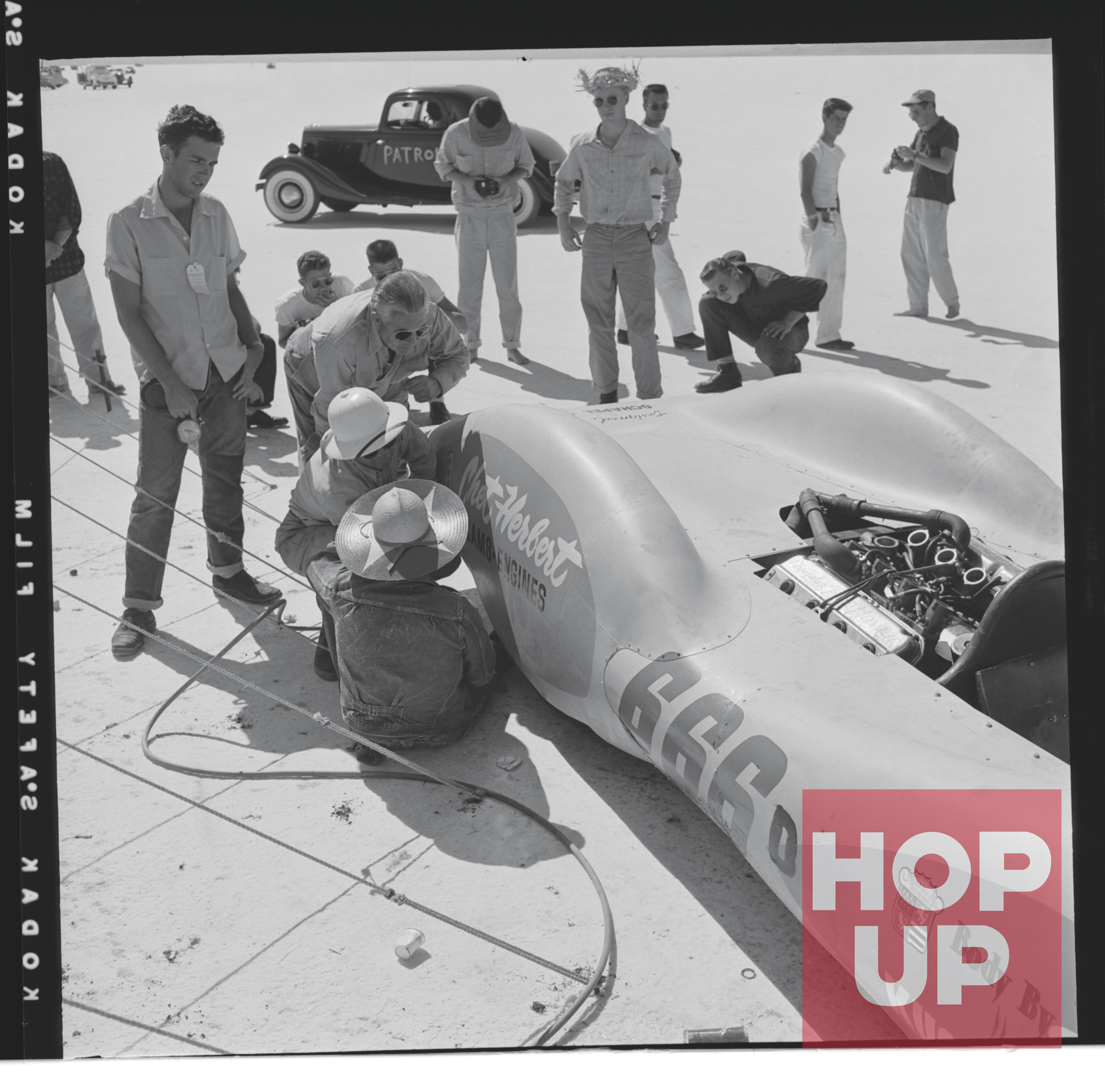

Beast III became a series of last-minute marathon sessions that would last all night. The car was ultimately completed deep into Speed Week, finally arriving on Friday- the fifth day of the meet- and stunning everyone who saw it with its graceful and intimidating beauty. Shot bright red, and with the appropriate 666 numbers on each side, the car was entered in the D-Streamliner class as the Herbert Cams Special. But just in case anyone had their doubts, the name Beast III was lettered across the nose. Chet and driver George Bentley were immediately fast, turning 182MPH, 197MPH, and then 211MPH in its first three runs. On the fourth run, Bentley missed a shift and tore out the clutch. Undeterred, Chet and crew spent all night welding the clutch solid so the car could be run with direct drive. The next morning Bentley was a no-show. The Herbert Cams crew kept moving the long car back in the line, but their driver was nowhere to be found. Finally, Art Chrisman- ignoring his father’s voice in his head telling him that he’d get his butt kicked if he got in that car- jumped at the chance to tear into the record books and slid his thin frame into the tight cockpit. His first run hit 219MPH. After some mechanical problems, the team was back out on the following day and Chrisman started thundering out progressively faster runs. First 224MPH, then 230, and then an astounding 235,991 run with a one-way best of 238,095 MPH. Over the years, Art Chrisman would spend a lot of time in all kinds of cars, but this would end up being the fastest he ever went.

Later in life, Chet would remember that weekend as his finest memory in racing. Art and his Dad and his brothers all having pitched in to finish the car and then the tremendous showing on the salt as a hard-earned reward.

Beast III would change streamliners forever. In 1952 it was the first U.S. automotive vehicle of any kind to use wind tunnel testing for maximum efficiency. It would set a new standard for design and science applied to land speed racing. By the time Chet was finished with Bonneville in ‘52, his red beauty, built largely by himself, would become the fastest single-engine car in the world and put Art Chrisman in the 200MPH Club, the fifth man so honored.

Chet was never content just piecing together cars from already available components. He needed to innovate and spent his life looking for new ways to improve existing performance. The beautiful Beast III would ultimately be returned to prominance and shown at the prestigious Pebble Beach Concours. It is now a proudly featured exhibit and owned by the Wally Parks NHRA Motorsports Museum in Pomona, Calif.

BEAST IV

Photo By Poole courtesy of the Kellogg Auto Archive

Anyone else would have been content to hold on to his dominant creation, working on small improvements to refine the new formula that you had invented and which had performed so well on an impossible build schedule. Not Chet Herbert. Chet was interested in making great leaps forward. His life was a constant reach for finding new methods to improve performance. For 1953 there would be an all-new Herbert Cams Special. Where most bystanders and builders looked at Beast III and saw a gorgeous and high tech work of rolling art, Chet saw plenty of room for improvement. As pretty and efficient as the sculpted body was, he thought that it would be possible to further reduce the mass and make it even faster through the unique salt flats atmosphere. Aerodynamicist Rod Schapel was back on board, the Bonneville bug having bitten hard. LeRoy Neumayer was a hot shoe who grew up in the hot rod hotbed of Compton, Calif. He was a dry lakes and drag racer who would go on to compete in circle-track, sprint cars and champ cars and later would end up with A.J. Foyt as an engine man. In 1953 Neumayer was a well-known gun for hire, often driving 2-3 different cars at drag meets. Chet asked Neumayer if he’d be interested in piloting a new car at speeds that up to this point he could only dream of. Bonneville held a mystical quality to most hot rodders and professional race drivers alike. He didn’t have to ask twice.

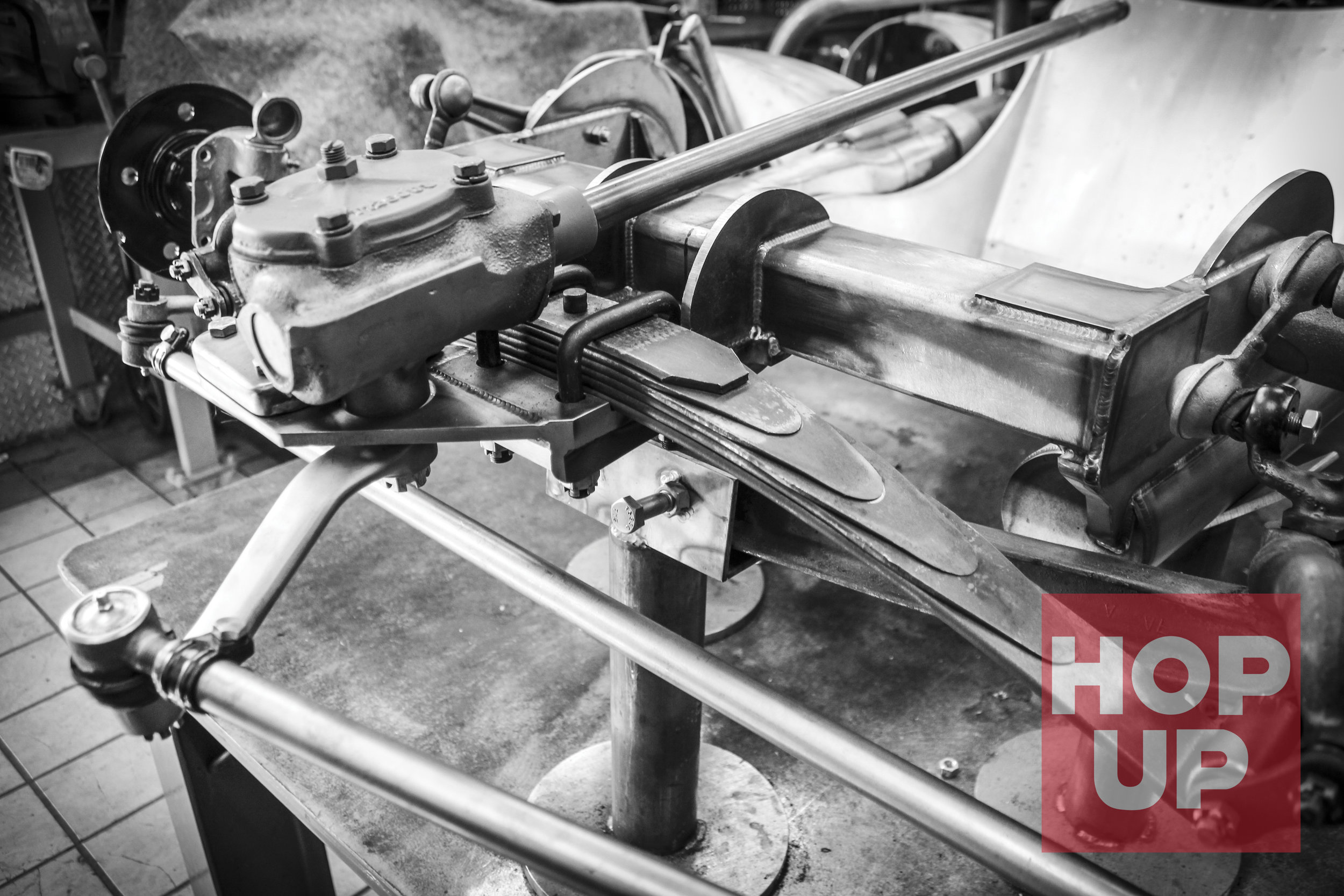

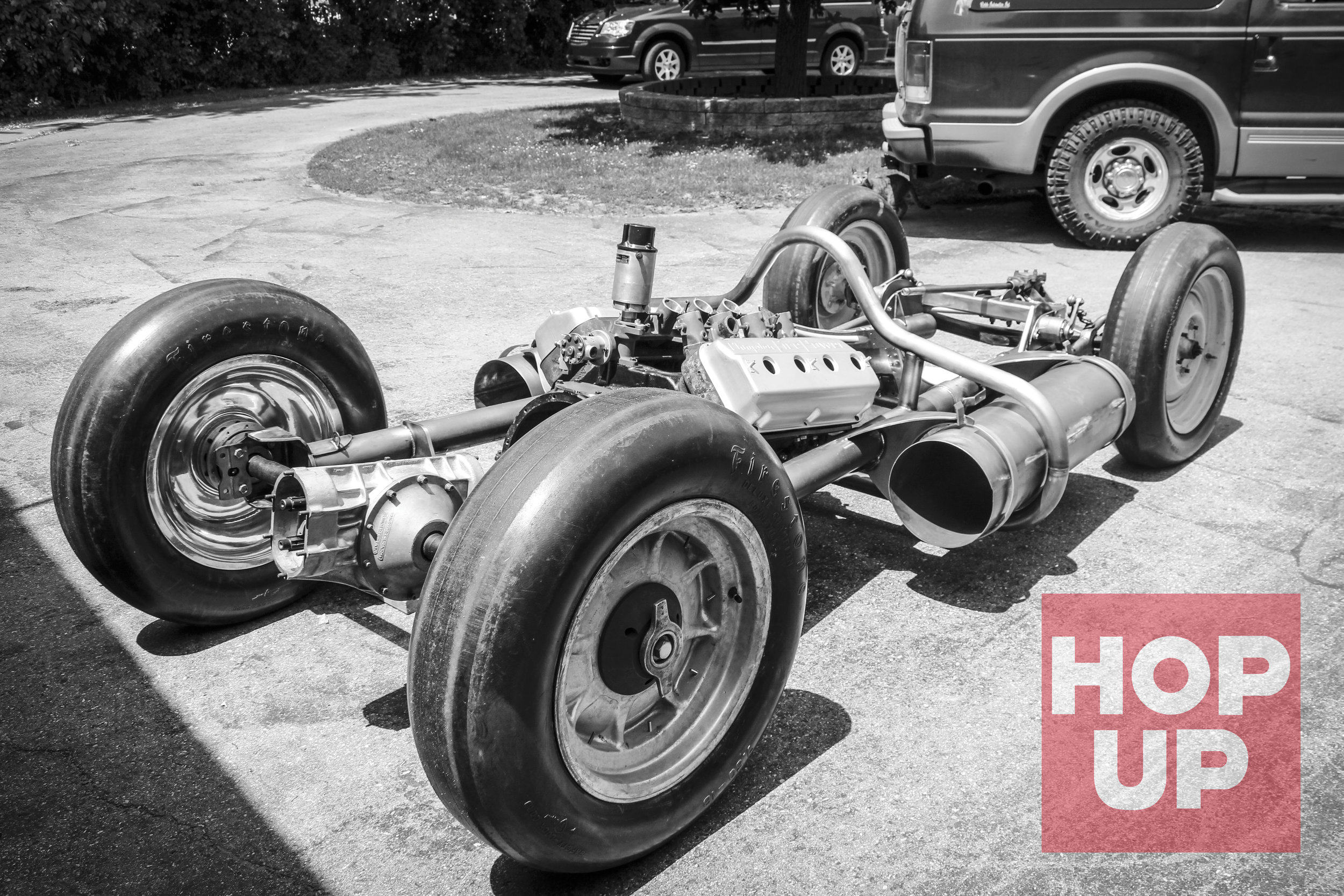

To mirror the previous year’s effort, the Beast IV project started late in the year, with only a matter of weeks available until Speed Week began. Again, Chet’s ability to inspire and lead a team through a challenging schedule would be tested. The layout of Beast IV was similar to III with a mid-mounted engine and an extreme forward driving position, but almost everything else was changed, refined and improved upon.

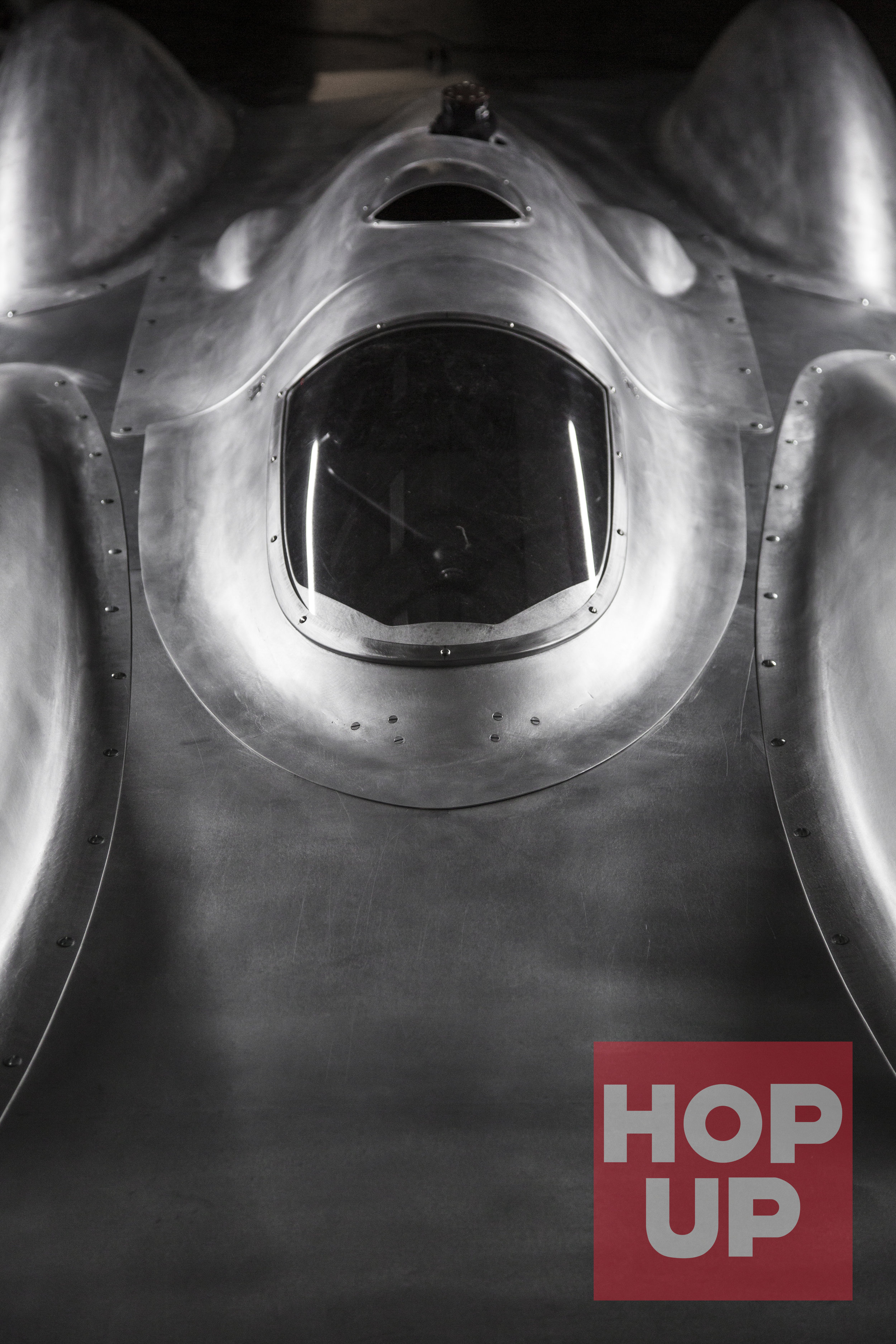

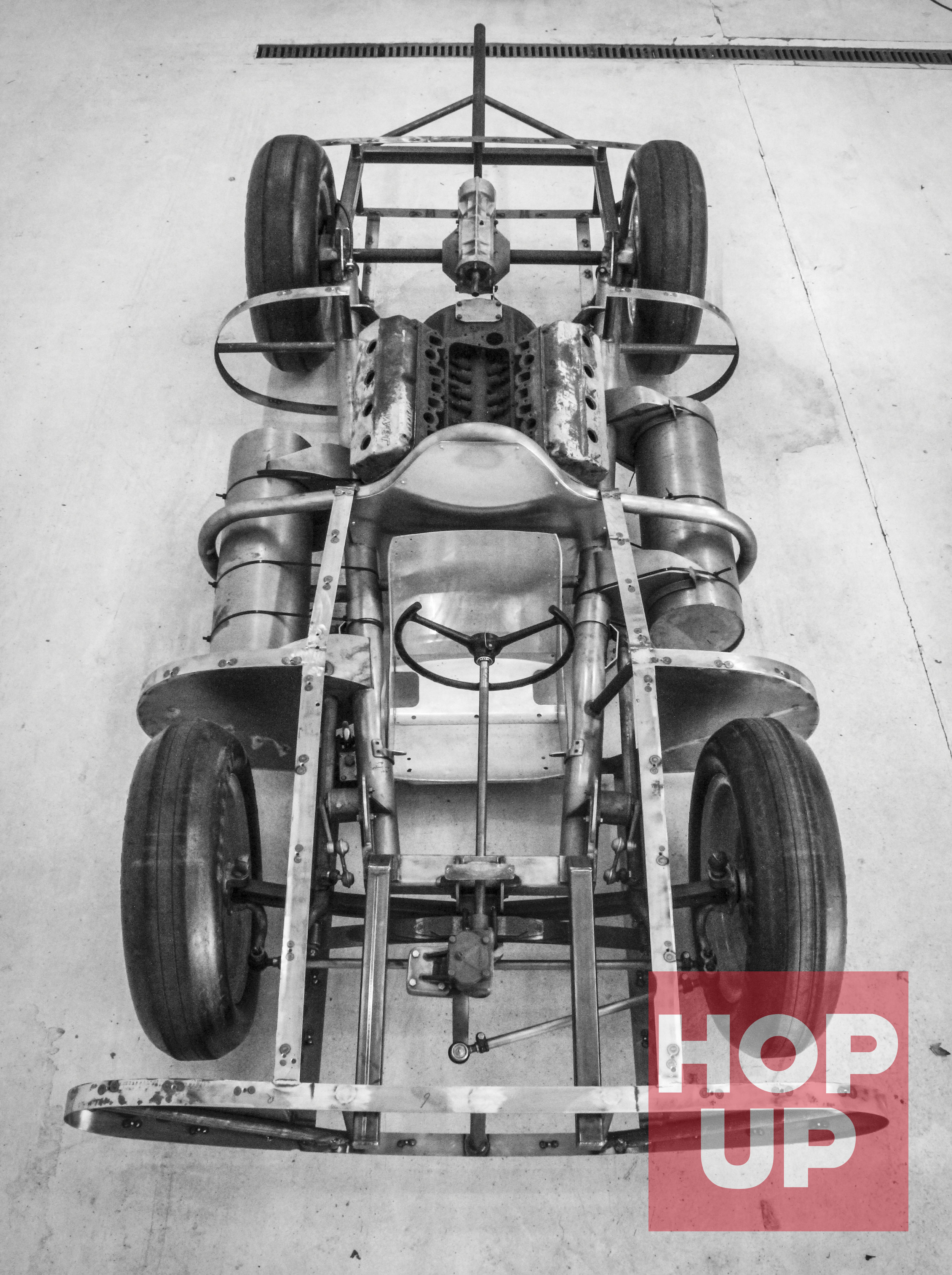

Beast IV was designed as a more compact package. A short, 95” wheelbase (down from the 108” Beast III) and a slightly larger 3.5” tube frame were specified. Fabrication began in Chet’s shop by Chet and Neumayer. As always, this was going to be a time-crunched last-minute effort, and typically, Chet was thinking about using something new and different in the engine bay. He had stumbled across an unfamiliar looking engine in a junkyard and found it interesting enough to buy. A little research revealed it to be a two-cycle, 183-inch four cylinder Weir Indianapolis engine, designed for the 1932 500. Chet thought that this oddball motor, with a few modifications, would be just the thing for his new land speed effort. In the chassis dept, Neumayer wasn’t a small jockey-sized driver, and allowances had to be made for his large frame. Luckily, as a part of the build team he was on hand for fitting in the tight forward cockpit. A period photo of him in the driver’s seat without the bodywork attached illustrated the small proportions of the car and the uncomfortable position he would have to endure in order to achieve glory on the salt.

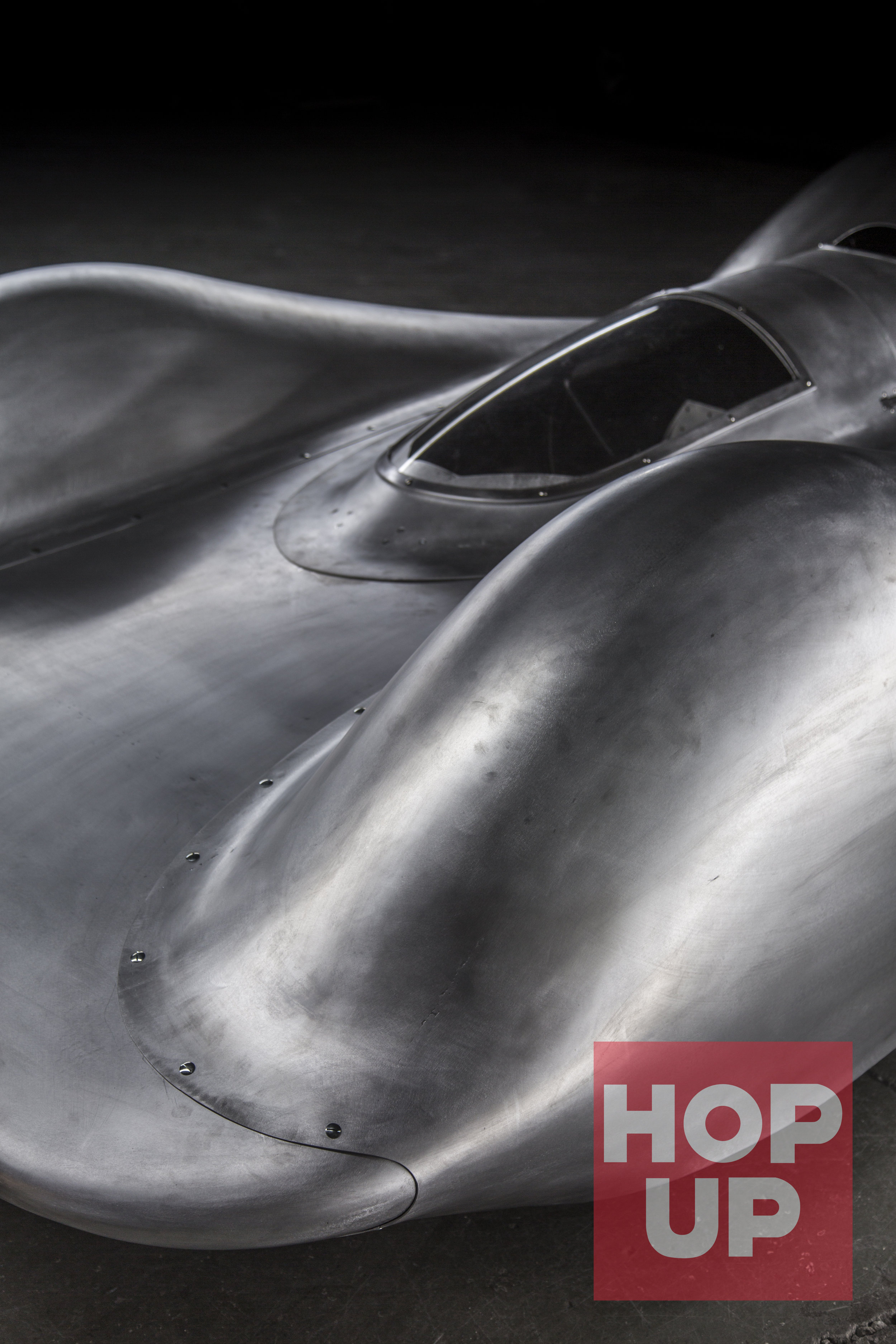

Rod Schapel designed an even tighter and lower body shape, reducing as much mass as possible and using as much wind tunnel time as he could squeeze in, between actual official Cal Tech projects. It is speculated that time constraints called for an aluminum body instead of the fiberglass used on Beast III.

With a finalized shape, Chet contacted the Barris brothers at their shop in Lynwood and asked if they would be interested in building an aluminum body for his new streamliner. They agreed, thinking that they had over a year to complete the job. Barris Kustoms had a big reputation in Los Angeles and was an incredibly busy shop. After clarifying that the body would be needed in only three weeks for the coming Speed Week, Chet used his well known his powers of persuasion and the Barris’ took on the job.

Just as in the previous year with Beast III, Chet’s idea of an exotic power plant ended dramatically with the Weir Indy motor disintegrating over the dyno room floor. The complicated body fabrication was nearing completion and the car suddenly didn’t have an engine. One of Chet’s customers, Gordon Potter, stepped up and volunteered the Hemi out of his 152MPH street roadster.

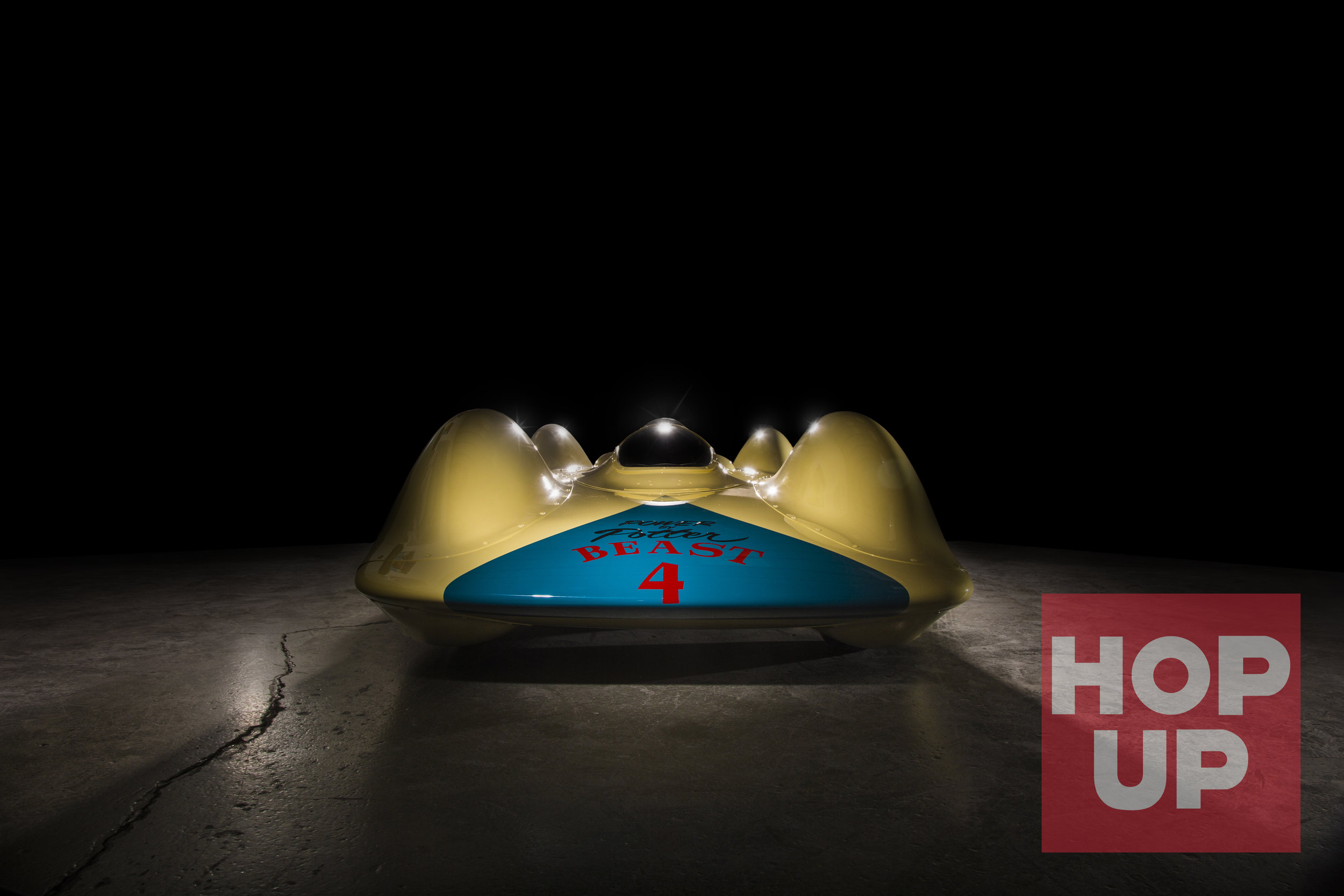

Another series of all-nighters followed with Chet and LeRoy making the necessary engine mounting modifications and then coupling the Hemi to a Pat Warren 2-speed quick-change rear end. 18” Halibrand magnesium knock-offs shod with Firestone racing tires made up the rear and Halibrand bolt-ons were mounted up front. Halibrand disc brakes actuated by hand controls made up the stopping power. The car sat so low that it was difficult to move it around the shop. Endless last minute tasks were performed until finally the car was ready. Instead of the solid red paint of III, Beast IV was quickly sprayed in a two-tone yellow/green mix and Chet Herbert Cams & Engines and Barris Kustom Auto were lettered on to the fully enclosed fenders. The Beast kept its 666 number. The end result may have been a little less attractive than Beast III, but all that mattered was how it would perform on the salt and there is nothing more beautiful than setting a new class record.

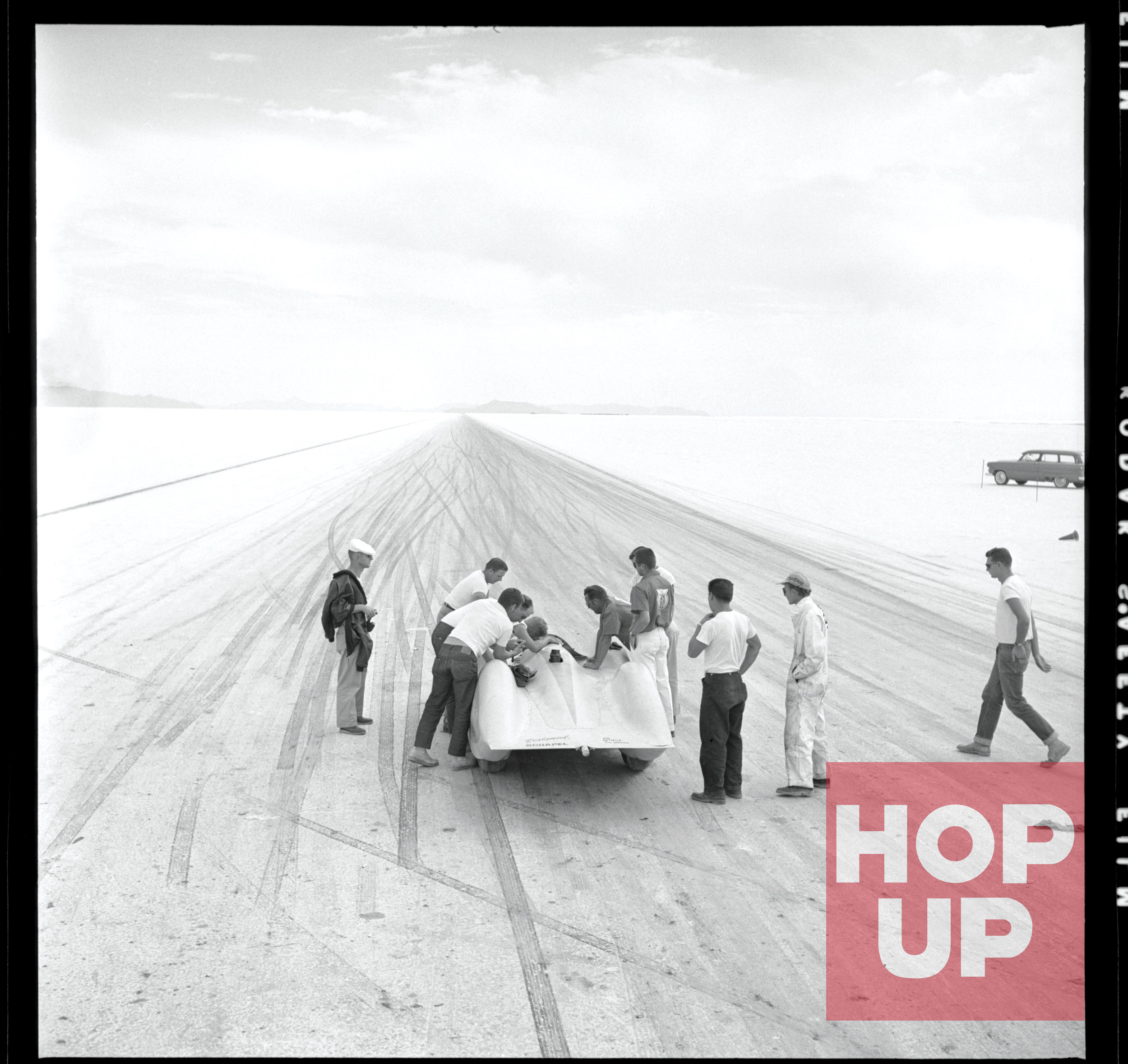

BONNEVILLE

The paint had hardly had a chance to dry, when it was carefully loaded onto an open trailer for the trip to the salt. As a repeat of the year before, the car arrived in Wendover late in the week on Friday afternoon. The Saturday morning line-up moved quickly. Chet, a constant presence next to the car in his wheelchair making last minute adjustments, would also drive the bump car, which had been equipped with hand controls. Neumayer was ready to get rolling for a shakedown run to make sure that everything was working correctly. The engine belched to life and the streamliner got up to speed and then launched away from the push car out into the white. Rod Schapel’s aerodynamic calculations again proved to be on the mark as Neumayer rocketed the new car to 211MPH on its first time out.

For 1953, twin-engine cars had been moved into Class E. This left Class D ripe pickings for Chet and his crew. The next day, LeRoy Neumayer joined the 200MPH club with a two-way record run of 211.39MPH. The record theirs, Chet and the crew were overjoyed. One week away was the FIA International Record Trials and the performance of Beast IV was a promising warm-up for the coming competition. Chet and Neumayer didn’t disappoint. A week later, in FIA Class B for larger engine cars, Beast IV broke records in the 10 kilometer and 5 mile distances. Neumayer had averaged 233.32MPH in the 5 mile, not bad for a last-minute build powered by a borrowed Chrysler pulled from a Model A street roadster.

Chet was back in ’54. In the days running up to Speed Week the gossip concerning the new Herbert Cams Beast V streamliner was running wild. Word had it that the new car would be powered by not one, but two of the exotic Novi V-8 Indianapolis engines. Chet’s inclination toward the unpredictable kept the rumor mill spinning.

When Chet and crew finally arrived in Wendover, Beast V was discovered to actually be a reworked version of Beast IV built to accommodate two Dodge V-8s, four-wheel drive, and returning driver LeRoy Neumayer shoehorned into a center position in between them.

The next day Neumayer was hammering the salt at full tilt with all sixteen cylinders howling across the flats. An extreme dampness in the atmosphere caused the clocks to malfunction as Beast IV/V shot by at an estimated 260MPH. The next day one of the reworked Jeep front axles broke and put an end to Chet Herbert’s weekend.

Chet would be back with the car in ’56 with two Chryslers installed but would not make it out to the salt. For 1957, Beast IV would be back again, now entered by Herbert, Hermann, and Walker. Still called Beast V, the car had undergone a significant transformation. Now, similar to the Kenz-Leslie streamliner with four-wheel drive, three small block Chevy V-8s and the driver’s cockpit relocated all the way to the rear. Still recognizable as Beast IV in spite of the changes in layout, the sleek beauty would fall victim to a series of technical problems that held their speed down to a disappointing 142.18MPH.

In 1958, the Beast was now five years old. In spite of this, the crew managed to get the 1000 cubic inches of Chevy power in synch enough for an impressive one-way shot of 272MPH. Attempting to capture the record on the return run, the center engine caught fire. Driver Dave Ryder managed to stop the car and extinguish the flames and that was the end of the ’58 effort. In ’59, a Phoenix, Arizona belly tank veteran named Ermie Immerso rolled in late in the week and caused a stir when it was revealed that he had bought Chet Herbert’s Beast IV (or V) and reconfigured it to two blown Chryslers with the driver situated back again in the middle. Ermie only made it out to the salt once, but that brutal run resulted in a 289MPH pass, slamming home the continued rightness of the base Beast IV platform and the Schapel-designed body.

Beast IV would change owners many times over the coming years and endure countless revisions in power and layout. Through it all, it would retain its familiar profile. Its last appearance at Bonneville would be in 1992 by owner/driver Bruce Johnson.

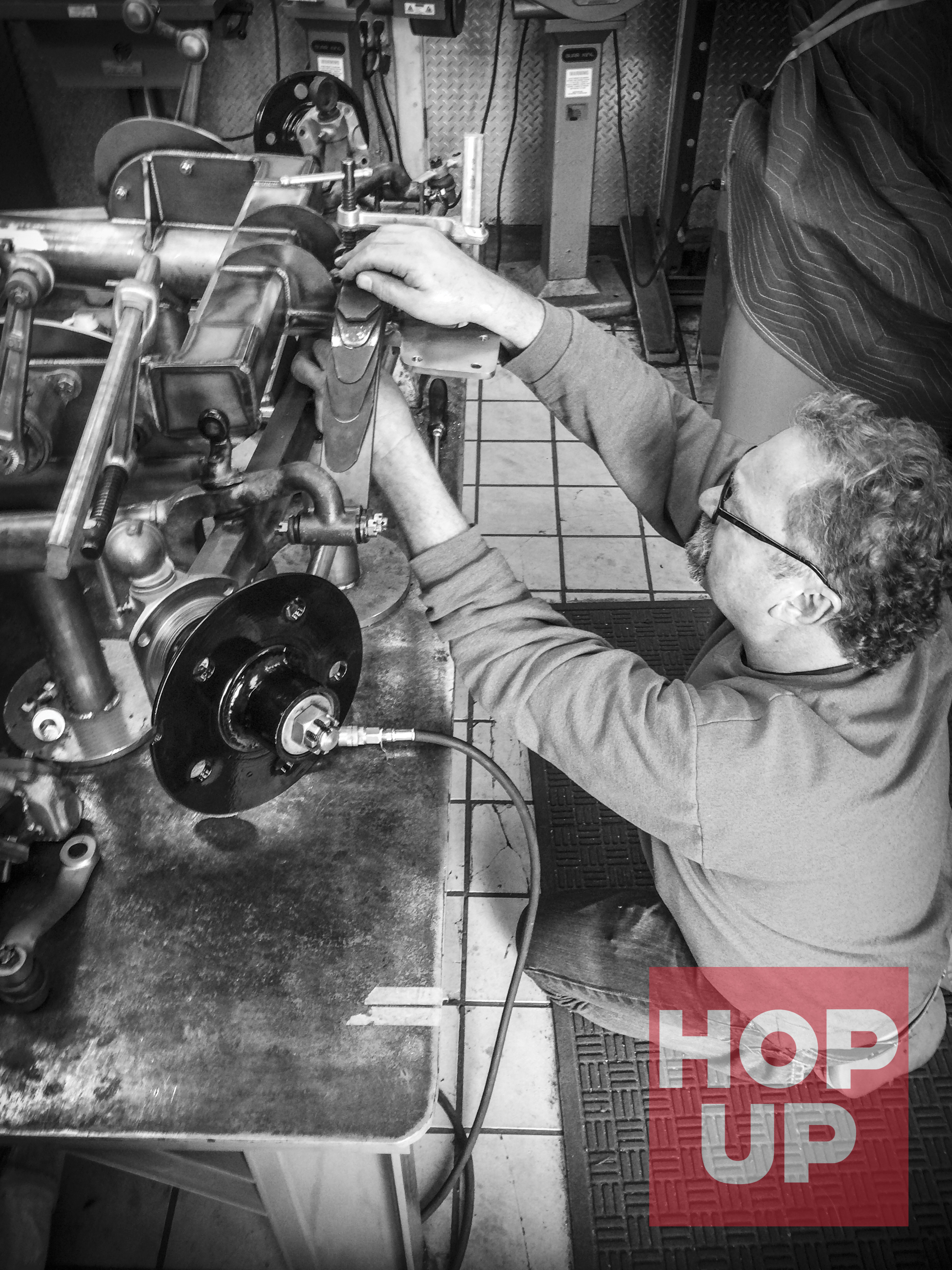

RESURRECTION- DAN WEBB

Like Chet Herbert, Dan Webb is a man at the top of his game. Dedicated to restoring and recreating historic racecars and hot rods, Dan is- like Chet Herbert- determined to leave his mark across the automotive landscape. Demanding, focused and a perfectionist, Dan’s history of diverse projects have proven him to be a craftsman with few peers. Webb Automotive Art has emerged as a key player in high-end automotive fabrication. Dan’s re-interpretation of the 1917 Harry Miller (driven by Barney Oldfield) Golden Submarine took the hot rod world by storm. Designed by Thom Taylor, Dan and his crew created a tribute to the famous racer that has been recognized as a true work of art, belonging as much in a museum as a garage. The design, detail and quality of construction continue to stun everyone who sees it. He would go on to recreate the Phil Remington Lakes Modified, one of the most beautiful cars to compete in the early dry lakes period and originally built by legendary fabricator and engineer Phil Remington. Dan was at the top of the list when the NHRA Museum was looking for someone with whom to trust the Beast IV project. Dan had recently recreated the first hot rod to break the 200MPH barrier, the famed Alex Xydias-Dean Batchelor So-Cal Streamliner of 1950. With the original wrecked and then sold for scrap, Dan would be trusted to recreate an accurate version of the long-lost car. Dan would refine the research techniques that are as important as fabrication skills in a project centered on a one-off vehicle originally built by enthusiastic hot rodders, and was essentially was made-up as they went along. Dan and his dedicated crew, daughter Ashley, son-in-law Cory Taulbert, Tracy Aitken and ace welder Wes Mishler would need to harness all of their skills and patience in order to resurrect the Beast IV. Forming the crucial aluminum skin would be the great Craig Naff, one of the world’s best metal shapers.

Beast IV had been obtained and then gifted to the NHRA Museum by David Duthu, a civil engineer and avid car collector. As a rare and valuable historic racer, the museum wanted to take it back to its first, most famous, and most beautiful version, the 1953 single-engine Nuemayer-driven version. When the old racer arrived at Dan’s shop, its condition was worse than expected. The decades of building and rebuilding the chassis to accommodate new engines and engine configurations, not to mention the constant cockpit relocation from front to back to center to back again, had left the car mixed-up and in need of most major components. Since there were never any technical drawings for these types of cars, the first job would be to collect as many original photographs and period magazine articles as could be located.

Dan is philosophical about taking on a project of this nature, “These things were built to win on the salt and had everything against them the minute they were built. They were meant to self-destruct.”

He goes on, “These guys didn’t have a lot of money. They were just trying to have a good time.”

Cory offers a balanced opinion, “For purists, the fact that Beast IV never suffered a major crash is something of a Catch-22. On one hand, the car survived, but on the other hand, it survived long enough to be rebuilt and altered many times, right up to its final Bonneville runs in 1992.”

He goes on, “The plan was to take it back to its first iteration. The biggest challenge was to figure out all the details of the car back in ’53. The car was somewhat well documented early on in the fabrication stage, but you can tell that when they really started thrashing on it to get it done, the photos stopped. A lot of the details of the original chassis were just not available.”

The later frame that arrived with the project wouldn’t work with the earlier ‘53/54 version so one of the first tasks at hand was to establish the exact measurements of the frame. Dan and his crew started digging into Chet’s frame fabrication. There were clear photos available and the exact dimensions could be established from them. Dan describes it like this, “You can get a lot from photos. If you see a 750/18 tire in a photo, you get a 750/18 and measure it, then you multiply and get the right dimensions.”

Endless digging for any useful information is always a part of the restoration process when dealing with unique and historic cars and can be a tedious exercise. Cory and Ashley would stare into grainy old photographs for hours at a time, slowly picking out the details- a Model A front axle, ’35-36 early wishbones, a military steering box.

But there is always a rush when a persisting part of the mystery is uncovered by a lucky find. Cory describes one such find. “We were fortunate to find a magazine article that was examining Chet’s planned 4-cyl engine. There was one front-on photo in this engine article that gave us the frame-tube diameter and the original wheelbase and wheel track for both front and rear. That one little snippet of a photo provided a huge amount of information. And that 4cyl ended up blowing up on the dyno, just like the year before with Beast III, so they went to the Chrysler Hemi.”

Ashley has been described as the ace detective, able to locate almost any of the unobtanium parts required. Many of the original components on these types of cars were rare even when they were first constructed. Sourcing these limited-run parts can be time consuming and expensive. Ashley describes some of her parts-gathering victories-“One of the rear Halibrand wheels we found right away. And then it took seven months to find the other one. We searched and searched for a Pat Warren 2-speed rear end. This is just not E-Bay type of stuff. We used social media and put the word out to people we know, networking. Of course, money always helps. My Dad did the Phil Remington car and the So-Cal Streamliner and it seems like its getting harder and harder for each car to locate some of the parts.”

Some components can prove to be beyond acquisition. The custom bell housing used on Beast IV perplexed Cory. “We spent almost a year researching that bell housing, trying to determine what it was. I thought it was agricultural-based and just something those guys grabbed. But it could also have been fabricated. On those early Chrysler blocks that transmission bolt pattern is a standardized SAE bolt pattern, so it could’ve been anything. But no one could name it so we just drew it up in CAD and had it machined from a single piece by Mike Curtis. I can’t believe how cool it turned out.”

The Pat Warren rear end was mounted upside down and needed a reverser box to correct the input shaft rotation. The original, as seen in a few photos, was clearly a hand- fabricated part. Cory modeled the part in CAD to match the Herbert-designed part and then had it machined by Bob and Rob Ida of Ida Automotive.

“Some of the throttle control and shifter mechanisms are best-guess. There weren’t any good cockpit photos available from the time, so we determined what would have been available to them, parts-wise. We also considered the layout on Beast III and made some educated guesses. Once we had the rolling chassis 90% done, we sent it to Craig Naff.”

Craig Naff likes to work alone in his shop nestled in Virginia’s Blue Ridge Mountains. With a reputation earned by his sheer genius with sheet metal, Naff is one of the finest metal shapers anywhere. He first attracted worldwide attention during his time with Boyd Coddington. He is the expert craftsman responsible for the incredible bodywork on ZZ Top’s CadZZilla, and then the Boyd Smoothster which was named America’s most beautiful Roadster at the ’95 Grand National Roadster Show in Oakland. Craig is recognized as one of the few people that can make an entire body from sheet metal and have doors, panels and the complicated inner compartments that don’t show on the outside line up perfectly. A master of his craft, his achievements are too many to mention and his talent is constantly in demand by custom vehicle builders demanding the finest body panels available. Creating the body for Dan Webb’s Golden Submarine tribute car again proved that no one can shape metal better than Craig Naff.

Once Beast IV was in his shop, Craig had to assess each panel and determine which pieces were originals. Then of those original pieces, judgment calls have to be made about whether they are good enough to be used. Salt and aluminum come together with obviously caustic results and nearly 40 years of Bonneville action had eaten into those panels. Working through the layers of paint and decay and patching, most of the body from the last version had to be scrapped. Only a few of the original pieces were able to be saved. Craig hand-formed the complex angles and curves that had been designed by Rod Schapel with aerodynamic efficiency in mind and made into three-dimensional reality by the Barris brothers. There is an old aviation adage that applies to cars as well, “If it looks right, it IS right.” That the car turned out beautiful was a lucky coincidence. Now, another craftsman took his turn with the Beast IV, pounding out history from bare sheets of aluminum.

With the body completed, the car returned to Dan Webb’s Michigan shop for final assembly details. Once finished, the car would continue its journey to Darryl Hollenbeck’s Vintage Color Studio for paint and lettering. Hollenbeck recently painted the 2016 America’s Most Beautiful Roadster winner ’32 roadster. At every show there is always an old-timer who looks at a freshly restored car and quips that it looks way better than anything that was actually around back in the day. One of those old men will probably be shuffling through the NHRA Museum sometime soon and say the same about the Beast IV.

Finally at rest and rejuvenated, with a future secured, Chet Herbert’s Beast IV will be both a treasured artifact from an earlier time in the motor age and an object of beauty to be admired and studied. Dan Webb considers the risks that were routinely ignored in the time of Beast IV. “ LeRoy Neumayer was a big kid, and I don’t know how he got into this car. There is a false sense of security with these things. We saw it in the So-Cal Streamliner, too. You sit real low and the bodywork wraps around you. And it’s just sheet aluminum. There is no roll cage. Beast IV was a little better than the So-Cal car, but only about 10% better. You’re sitting between two tanks, gas on one side and water on the other. If you flip the car, you have a choice- you can be burned to death by fuel or scalded to death by the hot water.”

Thinking further, he goes on, “Chet Herbert was a very positive man and people wanted to be around him. And he had a way of bringing out the best in people. But we have to remember that these things were only tools. Chet didn’t go easy on them and neither did the drivers.”

Chet Herbert had a drive and a will to innovate that was echoed by numerous performance-minded hot rodders of the golden age. Even confined to a wheelchair, or perhaps because of it, very few could match his list of achievements. And he would never lose the wild streak that had earned him a reputation aboard that stripped-down Harley on the streets of L.A. Trapped in a wheelchair, that wild streak would just change form and manifest itself as the wildest thing on the Bonneville salt that anyone had ever seen.